When building or upgrading your radio-controlled (RC) car, one of the most important decisions is choosing the right type of battery. The two main options are Nickel Metal Hydride (NiMH) and Lithium Polymer (LiPo) batteries. Both offer advantages and downsides. In this detailed comparison guide, we’ll examine all the key differences between NiMH and LiPo batteries for RC applications.

NiMH Batteries Overview

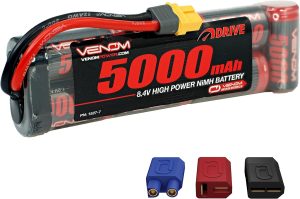

Nickel Metal Hydride batteries have been the long-time standard option for powering RC vehicles. Here are the core characteristics of NiMH packs:

- Use nickel and hydrogen to store energy

- Can provide high current output

- Low-cost and widely available

- 1.2V nominal voltage per cell

- Discharge performance decreases over time

- Hundreds of recharge cycles

- Not damaged by over-discharging

- Require full discharging to avoid the memory effect

- Heavier than lithium-based batteries

In the RC world, you’ll typically find NiMH packs with 4 to 8 cells for optimal high current output. This provides overall voltages between 4.8V to 9.6V when fully charged.

While NiMH has been a trusted RC battery choice for years, newer lithium technologies are giving them competition. Next, we’ll see how LiPo batteries compare.

LiPo Batteries Overview

Lithium Polymer batteries have surged in popularity in RC circles thanks to their high energy density. Here are the key attributes of LiPo packs:

- Use lithium-ion cells in a flexible pouch format

- Very high discharge rates to supply maximum current

- Lighter weight than most battery types

- 3.7V nominal voltage per cell

- Capacity and lifespan degrades faster than NiMH

- Charge/discharge performance stays consistent over time

- Requires more careful voltage monitoring and handling

- Around 500 recharge cycles under optimal conditions

- Can be damaged by over-discharging

LiPo packs for RC use often have 2 to 4 cells, providing 7.4V to 14.8V fully charged. Their high power-to-weight ratio makes them a favorite for applications favoring speed and acceleration.

Now that we’ve covered the background of each battery type, let’s directly compare their pros and cons.

NiMH vs LiPo: Key Comparison Points

Here we drill into the detailed differences between NiMH and LiPo batteries across a range of performance factors:

| Factor | NiMH | LiPo |

|---|---|---|

| Voltage | 1.2V per cell | 3.7V per cell |

| Specific energy | 30-80 Wh/kg | 130-240 Wh/kg |

| Discharge performance | Declines over time | Stays consistent |

| Lifespan | 500-1000 cycles | 300-500 cycles |

| Maintenance needs | Low | Higher |

| Sensitivity to over-discharge | Low | High |

| Weight | Heavier | Lighter |

| Cost | Lower | Higher |

Let’s unpack the key differences in more detail:

Voltage per cell: The higher 3.7V nominal voltage of LiPo cells compared to 1.2V for NiMH means less cells are required to achieve target voltages for RC use. This contributes to the lighter weight of LiPo packs.

Specific energy: LiPo batteries offer vastly higher energy densities in the range of 130-240 Wh/kg compared to 30-80 Wh/kg for NiMH. This also enables lighter pack weights.

Discharge performance: NiMH batteries slowly lose maximum discharge capacity over hundreds of cycles. LiPo cells maintain consistent high discharge rates throughout their lifespan.

Lifespan: Cycles until failure is shorter for LiPo at around 300-500 compared to 500-1000 cycles for well maintained NiMH packs.

Maintenance: LiPo batteries require more careful voltage monitoring, charging/discharging procedures, and storage conditions compared to more forgiving NiMH batteries.

Over-discharge: LiPo cells can be irreversibly damaged if discharged below around 3V per cell while NiMH batteries are not affected by over-discharge.

Weight: Thanks to the higher energy density, LiPo packs weigh substantially less than NiMH packs with the same capacity in watt-hours.

Cost: The specialized materials and construction of LiPo cells come at a higher price than inexpensive, mass-produced NiMH batteries.

As you can see, LiPo batteries outperform NiMH in power capabilities like voltage, discharge rate, and weight. But NiMH offers some pros like lower cost, less maintenance, and greater longevity that shouldn’t be overlooked.

LiPo vs NiMH: Real World RC Performance

How do the characteristics of LiPo and NiMH batteries translate to real world handling and performance in RC vehicles? Here’s how they compare:

Speed and acceleration – LiPo batteries excel in high-drain applications, able to supply the maximum current needed for rapid speed and acceleration. NiMH packs lose some performance at their upper current limits.

Climbing ability – The superior power-to-weight ratio of LiPo packs gives them the advantage in climbing steep slopes and hills without losing momentum compared to heavier NiMH packs.

Run time – Higher capacity LiPo packs provide longer run times between recharges. However mid-capacity NiMH packs can still deliver ample runtimes for casual use.

Responsiveness – LiPo batteries avoid the “voltage sag” under heavy load that NiMH batteries experience. This results in more consistent voltage and responsiveness when maneuvering.

Bashability – NiMH packs are less prone to damage from crashes, bumps, and mishandling compared to more delicate LiPo packs.

Newbie-friendliness – NiMH batteries are simpler to maintain and charge, more forgiving of mistakes, and lower cost. This makes them ideal for entry-level users.

So for maximum speed and power, LiPo batteries are the clear choice. But NiMH batteries remain a great option for hobbyists prioritizing affordability, durability, and hassle-free operation.

Choosing the Right Pack and Compatibility

When selecting a battery pack, you need to consider key factors like:

- Vehicle requirements – Choose batteries able to deliver sufficient current for your motor/engine setup. Consider the battery configurations used successfully by others with similar vehicles.

- Connector type – The battery must have a connector compatible with your ESC (electronic speed control unit). Common types are Tamiya, Deans, XT60, EC3.

- Voltage – Match the battery voltage to your ESC/motor specs. Too low voltage results in poor performance. Too high can fry electronics.

- Dimensions – Ensure the battery pack fits the allotted space in your vehicle or external mount. Measure dimensions carefully.

- Capacity – Higher mAh capacity means longer runtimes. But higher capacities require longer charging times.

- Cost – Batteries make up a significant portion of an RC vehicle’s overall cost. Weigh your budget and needs.

Installing a battery incompatible with your vehicle can cause poor handling or even damage to components. So always double-check compatibility specifications first.

Battery Care and Safety

Both battery types require proper usage and storage habits to maximize performance and avoid potential hazards:

LiPo safety:

- Never discharge LiPo cells below 3V per cell

- Don’t leave batteries unattended while charging

- Charge on non-flammable surfaces and use LiPo bags

- Properly dispose of physically damaged packs

NiMH safety:

- Use a smart charger with delta peak detection for automatic cutoff

- Don’t leave charging batteries unattended

- Store in a cool, dry place away from metal objects

General safety:

- Inspect packs for swelling or damage before charging

- Ensure correct battery polarity when connecting to ESC

- Disconnect battery after running vehicle

- Avoid short circuiting the battery terminals

Additionally, always use the balanced charger made for your specific battery pack and follow charging guidelines. Never try to charge packs with a mismatched charger.

Responsible handling and care is crucial to getting the most lifespan out of either battery while minimizing safety risks that can occur if misused or damaged.

Do You Need to Use Only One Type of Battery?

An advantage of RC vehicles is you aren’t necessarily locked into just one type of battery forever. Here are some scenarios where you may use both battery types:

- Use NiMH for low-intensity use, training, or new drivers. Then use LiPo for experienced racers wanting max speed.

- Have NiMH packs for bashability and LiPo for optimized performance.

- Use LiPo only when you plan to run the RC heavily. Use NiMH on light-run days to preserve your LiPo lifespan.

- Equip a high-performance LiPo battery for speed runs. Bring spare NiMH packs for extended casual running time.

Just be sure your RC components are compatible with both battery types in terms of voltage, connector type, and discharge capabilities.

Key Takeaways – NiMH vs LiPo Batteries

- NiMH batteries offer affordability, durability, and hassle-free use. But they are heavier and lose performance over time.

- LiPo batteries deliver superior power, acceleration, and lightweight. But need careful handling and cost more.

- Match your battery choice to your vehicle’s electrical specs and your experience level.

- LiPo batteries are the top choice to maximize speed and climb ability. NiMH suits beginners and budget buyers.

- Use proper charging and storage habits to optimize safety and battery lifespan.

Final Thoughts

At the end of the day, whether to use NiMH or LiPo batteries comes down to your RC application and priorities as a hobbyist. If chasing maximum speed and power is critical, LiPo packs are the clear winner. They offer game-changing performance improvements over NiMH – albeit at increased cost and handling precautions.

But for casual hobbyists who prioritize reliability, battery life, and cost savings, tried-and-true NiMH packs remain a great choice. They offer ample speed for recreational runs plus forgiving maintenance and safety.

Hopefully, this detailed LiPo vs NiMH battery breakdown gives you the knowledge to pick the right type for your next RC build or upgrade. Let me know if you have any other battery-related questions!