Picture this: you’re at the starting line of an intense RC car race, adrenaline pumping through your veins. The difference between victory and defeat lies in the power and efficiency of your car’s motor. Will you settle for the limitations of a brushed motor, or will you embrace the unparalleled performance of a brushless motor? In the world of remote-controlled cars, choosing the right motor is not just a matter of preference – it’s a game-changer that can elevate your racing experience to new heights.

As RC car enthusiasts, we’re always seeking ways to enhance speed, torque, and overall performance. The motor is the heart of your RC car, dictating its capabilities and longevity. In this comprehensive article, we’ll explore the remarkable benefits of brushless motors compared to their brushed counterparts. Get ready to discover why brushless motors are the preferred choice for serious hobbyists and competitive racers alike.

Understanding Brushless and Brushed Motors

Before we dive into the advantages of brushless motors, let’s establish a solid understanding of both motor types.

Brushed Motors

Remote Control Car 1:18 Scale Brush Motor with Two Rechargeable Batteries

- PHOUPHO brand new 4WD remote control car with new shell paint and chassis structure, four-wheel drive performance acceleration effect and cornering response is faster and more sensitive, equipped with the latest developed RC380 motor, the highest speed can up to 45km/h.

Key Points:

- Rely on physical brushes and a commutator for operation

- Brushes maintain contact with commutator segments

- Friction and wear lead to reduced performance over time

- Require regular maintenance

Brushed motors have been a staple in the RC car world for years. These motors rely on a simple yet effective design involving physical brushes and a commutator. The brushes, typically made of carbon, maintain contact with the commutator, which is divided into segments. As the motor rotates, the brushes alternate between segments, reversing the polarity and ensuring continuous motion.

While brushed motors have served the RC community well, they do have some inherent limitations. The physical contact between the brushes and commutator leads to friction, heat generation, and eventual wear. This wear can result in reduced performance over time and requires regular maintenance to keep the motor running smoothly.

Brushless Motors

DEERC 1:14 Fast Brushless RC Cars for Adults

- Unleash the speed demon within! The DEERC RC car, armed with a 2847 4000KV brushless motor and dual 3S batteries, rockets past 75+ KMH (46+ MPH), delivering heart-pounding thrills for as long as you can handle.

Key Points:

- Utilize electronic speed controllers (ESCs) for power management

- Eliminate the need for physical brushes and commutator

- Offer higher speeds, greater efficiency, and less wear

- Require minimal maintenance

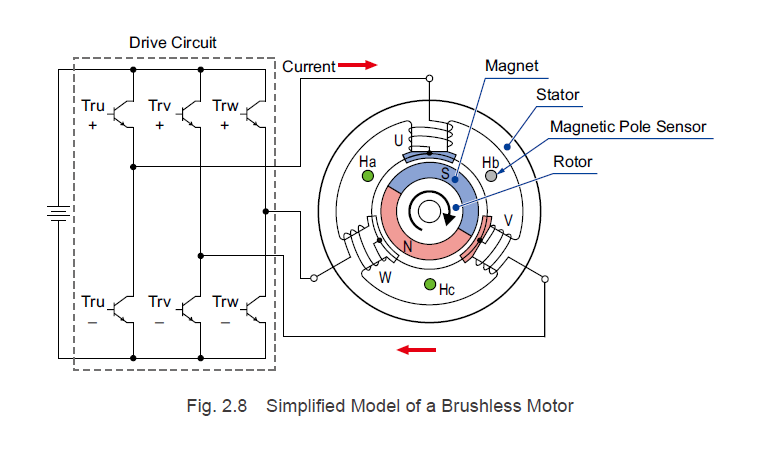

Enter brushless motors – the cutting-edge technology that has revolutionized the RC car industry. Unlike brushed motors, brushless motors eliminate the need for physical brushes and a commutator. Instead, they rely on electronic speed controllers (ESCs) to manage power distribution.

In a brushless motor, the ESC sends precise electrical signals to the stator windings, generating a magnetic field that interacts with the permanent magnets on the rotor. This interaction creates a powerful and efficient rotation, allowing brushless motors to deliver unmatched performance.

The absence of brushes means less friction, reduced heat generation, and minimal wear. Brushless motors can operate at higher speeds, handle greater voltages, and provide consistent power output, making them the go-to choice for serious RC enthusiasts.

Performance Comparison

Key Points:

- Brushless motors offer superior acceleration and top speeds

- Brushless motors provide higher torque and efficiency

- Ideal for competitive racing and demanding off-road conditions

When it comes to performance, brushless motors leave brushed motors in the dust. Let’s examine some key metrics and explore how brushless motors excel in each area.

| Performance Metric | Brushed Motors | Brushless Motors |

| Torque | Moderate | High |

| Speed | Moderate | Extremely High |

| Efficiency | Lower | Significantly Higher |

| Heat Generation | Higher | Minimal |

Brushless motors offer unparalleled acceleration and top speeds compared to brushed motors. The absence of friction allows for lightning-fast rotation and instant power delivery. This makes brushless motors the ideal choice for competitive racing scenarios, such as drag racing or high-speed off-road adventures. The extra torque and speed can make all the difference in achieving the perfect launch or navigating challenging terrains.

Efficiency is another area where brushless motors shine. By eliminating the power loss associated with brush friction, brushless motors can convert a higher percentage of electrical energy into mechanical power. This translates to longer runtimes, cooler operating temperatures, and the ability to push your RC car to its limits without compromising performance.

Durability and Maintenance

Key Points:

- Brushless motors offer exceptional durability and longevity

- Brushless motors require minimal maintenance

- Brushed motors are subject to wear and performance degradation

When it comes to longevity and maintenance, brushless motors have a clear advantage over brushed motors. Let’s explore the durability differences and the practical implications for RC car owners.

Lifespan and Performance Degradation

Brushed motors, by nature, are subject to wear and tear due to the constant contact between the brushes and the commutator. Over time, the brushes erode, leading to reduced performance and eventual failure. The lifespan of a brushed motor depends on factors such as usage frequency, operating conditions, and maintenance habits.

As brushed motors wear down, you may notice a gradual decline in speed, power, and efficiency. The performance degradation can be frustrating, especially if you’re in the middle of a race or an exciting RC adventure. Brushed motors may require frequent brush replacements to maintain optimal performance, adding to the overall maintenance burden.

On the other hand, brushless motors offer exceptional durability and longevity. The absence of brushes eliminates the primary wear point, resulting in a motor that can outlast its brushed counterpart by a significant margin. Brushless motors can run for extended periods without experiencing performance drop-off, providing consistent power and reliability.

Maintenance Requirements

Maintaining a brushed motor can be a time-consuming and complex process. Regular maintenance tasks include:

- Cleaning the commutator and brushes to remove debris and ensure smooth contact

- Replacing worn brushes to restore performance

- Lubricating bearings to reduce friction and prolong motor life

- Monitoring and replacing worn or damaged parts

Neglecting these maintenance tasks can lead to reduced efficiency, overheating, and premature motor failure. For RC car enthusiasts who want to spend more time enjoying their hobby and less time tinkering with motors, the maintenance requirements of brushed motors can be a significant drawback.

Brushless motors, in contrast, require minimal maintenance. The lack of brushes means fewer moving parts and less wear, resulting in a motor that can run reliably for extended periods without the need for frequent servicing. Brushless motors are built to withstand the rigors of high-performance racing and demanding off-road conditions.

Cost Analysis

Key Points:

- Brushless motors have a higher initial cost

- Brushless motors offer long-term cost savings

- Consider the total cost of ownership when making a decision

When considering the switch to brushless motors, cost is often a significant factor. While brushless motors have a higher initial price point compared to brushed motors, it’s crucial to evaluate the long-term cost implications.

| Motor Type | Price Range | Long-Term Value |

| Brushed | $20 – $100 | Lower |

| Brushless | $50 – $200+ | Significantly Higher |

At first glance, the higher upfront cost of brushless motors may seem daunting. However, it’s essential to consider the long-term value they provide. Brushless motors offer extended longevity, reduced maintenance costs, and improved performance, making them a smart investment for serious RC enthusiasts.

While brushed motors may have a lower initial cost, they often require frequent replacements and upgrades due to wear and tear. The cumulative cost of replacing brushes, servicing the motor, and potentially purchasing a new motor altogether can quickly add up over time.

In contrast, brushless motors, with their robust construction and minimal maintenance requirements, can provide years of reliable performance without the need for constant replacements or repairs. The higher initial investment pays off in the form of reduced long-term costs and a more enjoyable RC experience.

Energy Efficiency

Key Points:

- Brushless motors have higher energy efficiency ratings

- Brushless motors offer longer runtimes and cooler operating temperatures

- Brushless motors align with sustainability and environmental consciousness

Energy efficiency is a crucial consideration for RC car owners, as it directly impacts battery life and overall performance. Brushless motors have a significant advantage over brushed motors in terms of energy efficiency.

| Motor Type | Energy Efficiency Rating |

| Brushed | 60% – 80% |

| Brushless | 85% – 95% |

The higher efficiency ratings of brushless motors translate to several practical benefits. Firstly, brushless motors can extract more power from the same battery capacity, resulting in longer runtimes and more extensive racing sessions. This means you can enjoy your RC car for extended periods without the need for frequent battery swaps or recharges.

Real-world testing and user experiences have consistently demonstrated the superior battery life of brushless motors. For example, in a side-by-side comparison using identical battery packs, a brushless motor-powered RC car may run for 30-40% longer than its brushed counterpart. This extra runtime can make a significant difference in competitive racing scenarios or during extended off-road adventures.

The efficiency of brushless motors also contributes to cooler operating temperatures. By minimizing power loss through heat generation, brushless motors can maintain optimal performance even under demanding conditions. This not only prolongs the lifespan of the motor but also reduces the risk of overheating and potential damage to other components.

Moreover, the energy efficiency of brushless motors aligns with the growing emphasis on sustainability and environmental consciousness within the RC community. By opting for a more efficient motor, RC car owners can reduce their overall energy consumption and contribute to a greener hobby.

User Experience and Feedback

Key Points:

- Brushless motors deliver a superior user experience across skill levels

- Positive feedback from beginners, intermediate racers, and experienced enthusiasts

- RC communities and forums highlight the benefits of brushless motors

The opinions and experiences of RC car enthusiasts provide valuable insights into the real-world benefits of brushless motors. Let’s hear from users who have made the switch and discover how brushless motors have transformed their RC experience.

Beginner Perspective

“As a newcomer to the RC car hobby, I was initially overwhelmed by the motor options. After doing some research, I decided to invest in a brushless motor, and I couldn’t be happier with my decision. The performance is incredible, and I can run my car for longer without worrying about battery life.” – Mark N.

Intermediate Racer

“Upgrading to a brushless motor was a game-changer for my racing performance. The instant acceleration and high top speeds have given me a competitive edge on the track. Plus, the reduced maintenance has allowed me to focus more on honing my racing skills rather than constantly tinkering with my motor.” – Emily R.

Experienced Enthusiast

“I’ve been in the RC car hobby for over a decade, and I can confidently say that brushless motors are the future. The durability, efficiency, and raw power they offer are unmatched. I’ve seen significant improvements in my lap times and overall racing experience since making the switch.” – Alex T.

These testimonials highlight the positive impact brushless motors have had on users across different skill levels and interests. From beginners seeking reliable performance to experienced racers chasing podium finishes, brushless motors have proven to be a transformative upgrade.

Online forums and RC communities are filled with countless stories of satisfied users who have embraced brushless technology. The consensus is clear: brushless motors deliver a superior user experience, offering enhanced performance, longer runtimes, and reduced maintenance hassles.

FAQ

Q. Are brushless motors compatible with all RC cars?

A. Brushless motors are compatible with most modern RC cars designed for brushless systems. However, it’s essential to check your car’s specifications and ensure that the motor and ESC are compatible with your specific model.

Q. How do I install a brushless motor in my RC car?

A. Installing a brushless motor typically involves the following steps:

- Remove the existing brushed motor and ESC.

- Mount the brushless motor in the designated motor mount.

- Connect the three motor wires to the ESC according to the manufacturer’s instructions.

- Secure the ESC in a suitable location within the car.

- Calibrate the ESC and configure the settings based on your preferences.

Q. What maintenance is required for brushless motors?

A. Brushless motors require minimal maintenance compared to brushed motors. Regular maintenance tasks include:

- Keeping the motor clean and free from debris.

- Ensuring proper lubrication of the bearings.

- Checking the motor’s mounting and wiring for any signs of damage or wear.

Q. Can I use a brushless motor with a NiMH battery?

A. While brushless motors are commonly used with LiPo batteries due to their higher voltage and discharge capabilities, they can also be used with NiMH batteries. However, the performance may not be as impressive as with LiPo batteries, and the runtime may be shorter.

Buying Guide

When selecting a brushless motor for your RC car, consider the following factors:

- Motor Size: Choose a motor that fits your car’s specific requirements. The motor size is typically indicated by a four-digit number (e.g., 3650, 2430) that represents the motor’s dimensions.

- KV Rating: The KV rating indicates the motor’s RPM per volt. A higher KV rating means faster speed but lower torque. Consider your car’s gearing and desired performance when selecting the KV rating.

- Compatibility: Ensure that the brushless motor is compatible with your car’s ESC and battery system. Check the manufacturer’s specifications and recommendations.

- Brand and Quality: Opt for reputable brands known for producing high-quality brushless motors. Read reviews and seek recommendations from experienced RC enthusiasts to make an informed decision.

- Budget: Determine your budget and look for the best value within your price range. Keep in mind that higher-priced motors often offer better performance and durability.

Future of RC Motors

As technology continues to advance, the world of RC motors is also evolving. One notable trend is the rise of sensorless brushless motors. These motors eliminate the need for hall sensors, making them more compact and lightweight. Sensorless motors rely on advanced algorithms and back EMF detection to determine the rotor’s position and optimize performance.

The advantages of sensorless brushless motors include:

- Reduced complexity and fewer components

- Lower cost compared to sensored brushless motors

- Improved durability due to the absence of delicate sensors

- Potential for higher RPM and more aggressive performance

While sensorless brushless motors have some limitations in terms of low-speed performance and smooth startup, continuous advancements in ESC technology are addressing these challenges. As sensorless motors become more refined, they may become the preferred choice for certain RC applications.

Another exciting development in the world of RC motors is the increasing adoption of direct drive systems. Direct drive setups eliminate the need for gears, belts, or chains, connecting the motor directly to the wheels. This configuration offers several benefits, including reduced drivetrain losses, improved efficiency, and instant power delivery.

As the RC hobby continues to push the boundaries of performance and innovation, enthusiasts can expect to see further advancements in motor technology. From high-efficiency designs to integrated smart features, the future of RC motors promises to bring even more excitement and possibilities to the world of radio-controlled cars.

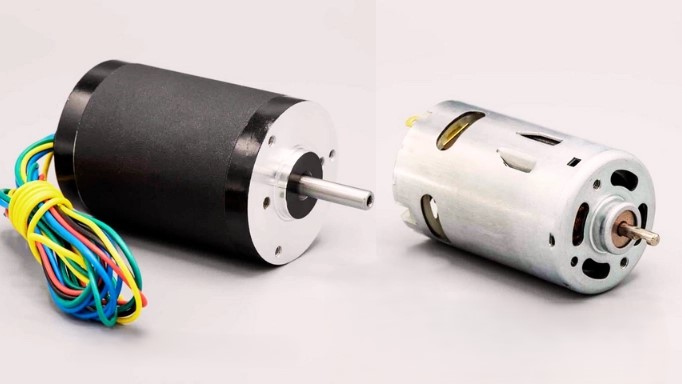

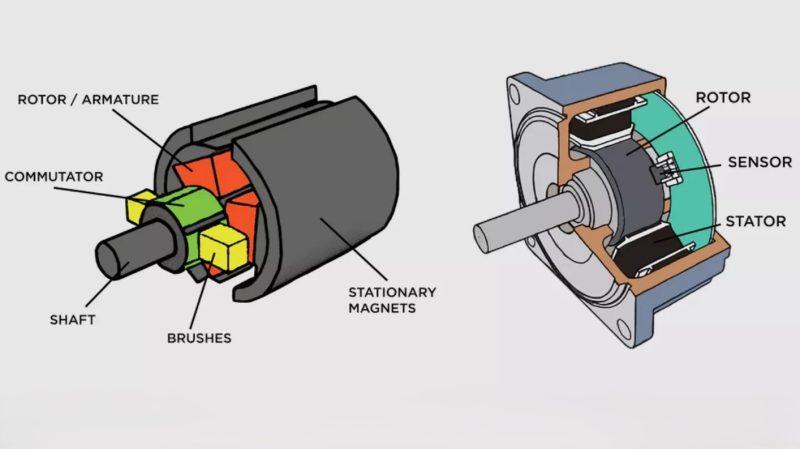

Visual Comparison

To better understand the differences between brushed and brushless motors, let’s take a visual look at their components and working principles.

BRUSHED VS BRUSHLESS

As you can see, brushed motors have physical brushes and a commutator, while brushless motors eliminate these components and rely on electronic speed controllers (ESCs) for power management.

In a brushless motor, the ESC sends electrical signals to the stator windings, creating a rotating magnetic field that interacts with the permanent magnets on the rotor, causing it to spin.

Real-world Examples

Many popular RC car models have seen significant performance improvements after switching to brushless motors. For example:

- The Traxxas Rustler VXL, a best-selling stadium truck, experienced a 70% increase in top speed and improved acceleration after upgrading to a brushless power system.

- The Arrma Kraton 6S BLX, a high-speed monster truck, delivers blistering speeds of over 60 mph thanks to its powerful brushless motor and optimized gearing.

- The Losi Tenacity SCT, a short course truck, showcases impressive speed and runtime with its brushless motor, outperforming its brushed counterparts on the track.

These real-world examples demonstrate the tangible benefits of brushless technology in various RC car categories, from off-road vehicles to racing machines.

Environmental Impact

In addition to performance advantages, brushless motors also offer environmental benefits. Their higher efficiency means they consume less energy compared to brushed motors, resulting in lower power consumption and extended battery life. This translates to fewer battery replacements and reduced waste over time.

Furthermore, the increased durability of brushless motors leads to a longer product lifespan, minimizing the need for frequent replacements and ultimately contributing to a more sustainable hobby. By choosing brushless motors, RC car enthusiasts can reduce their environmental impact while enjoying superior performance.

Future Advancements

As technology continues to evolve, the world of RC motors is poised for exciting advancements. One promising development is the rise of sensorless brushless motors, which eliminate the need for hall sensors, resulting in more compact and lightweight designs. These motors rely on advanced algorithms and back EMF detection to optimize performance, offering benefits such as reduced complexity, lower cost, and improved durability.

Another emerging trend is the adoption of direct drive systems, which connect the motor directly to the wheels, eliminating the need for gears, belts, or chains. Direct drive setups offer advantages like reduced drivetrain losses, instant power delivery, and enhanced efficiency. As these technologies mature, they have the potential to revolutionize the RC car landscape, pushing the boundaries of performance and efficiency even further.

Looking ahead, we can anticipate further innovations in brushless motor technology, such as high-efficiency designs, integrated smart features, and advanced cooling solutions. These advancements will continue to shape the future of the RC hobby, providing enthusiasts with even more powerful, reliable, and environmentally-friendly options for their beloved RC cars.

Conclusion

In the dynamic world of RC cars, the choice between brushed and brushless motors can significantly shape your overall experience. While brushed motors have been a reliable workhorse for years, the advent of brushless technology has revolutionized the hobby, offering unparalleled performance, durability, and efficiency.

Throughout this comprehensive article, we’ve explored the numerous benefits of brushless motors compared to their brushed counterparts. From the blistering acceleration and high top speeds to the extended motor lifespan and reduced maintenance requirements, brushless motors have proven their superiority in every aspect.

Whether you’re a competitive racer seeking every advantage on the track or a passionate hobbyist looking to maximize your RC car’s potential, investing in a brushless motor is a decision that will elevate your experience to new heights. The enhanced performance, longer runtimes, and overall reliability provided by brushless motors make them the clear choice for serious RC enthusiasts.

As you embark on your next RC adventure, consider the transformative power of brushless motors. Embrace the cutting-edge technology that has redefined the hobby and unlock the full potential of your RC car. With a brushless motor at the heart of your machine, you’ll experience the thrill of unmatched speed, the satisfaction of minimal maintenance, and the joy of pushing the boundaries of what’s possible.

So, are you ready to make the switch to brushless? Invest in the future of RC cars and experience the difference for yourself. Get ready to leave the limitations of brushed motors behind and embark on a journey of endless possibilities with the power of brushless technology.

Read Other Posts

- Exploring Niche Categories in the RC Community: Rock Crawling, Sand Dunes, and More

- How to Fine-Tune RC Car Servo Speed Like a Pro: Step-by-Step Guide (2024)

- RC Car Tire Showdown: Foam vs. Air – Which Setup Will Elevate Your Ride?

- Specialty RC Builds and Modifications: DIY Amphibious Cars, Spoilers, and Off-Road Conversions

- Trends in RC Gadgets and Accessories: Enhancing Performance, Control, and Aesthetics