Imagine this: You’re racing your RC buggy on a challenging off-road track, battling for position as you approach a series of tight, sandy turns. Suddenly, your car loses traction, sliding sideways and allowing your opponents to overtake you. Frustrated, you wonder what went wrong. The answer often lies in one critical component: your differential.

The differential is the unsung hero of your RC car, quietly working to distribute power and maintain control across various terrains. In this comprehensive guide, we’ll dive deep into the world of differentials, exploring different types, terrain-specific optimizations, advanced tuning techniques, and essential maintenance tips. Whether you’re a seasoned racer looking to shave seconds off your lap times or a casual enthusiast seeking better all-around performance, understanding and optimizing your differential is key to unlocking your RC car’s full potential.

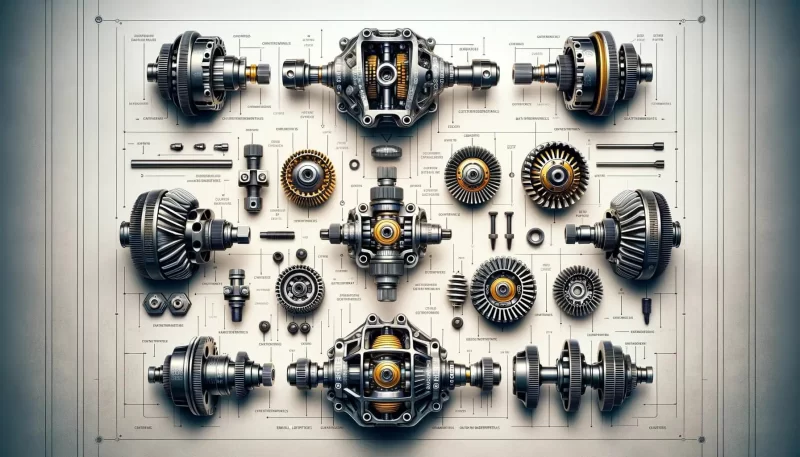

Understanding the Heart of Your RC Car: The Differential

At its core, a differential allows your RC car’s wheels to rotate at different speeds while maintaining power delivery to both sides. Think about a full-size car making a turn: the outer wheels must travel a greater distance than the inner wheels. Without a differential, the wheels would slip or skid, causing loss of traction, excessive tire wear, and unpredictable handling.

In the world of RC cars, differentials come in several types, each with unique characteristics suited for different terrains and driving styles.

Types of Differentials

| Type | Key Features | Pros | Cons |

| Open Differential | – Allows wheels to rotate independently – Uses gears to ensure rotation in same direction | – Smooth cornering – Reduced tire wear – Excellent for high – grip surfaces | – Limited performance on loose surfaces – Prone to power loss with one-wheel traction loss |

| Limited-Slip Differential (LSD) | – Allows differential wheel speeds – Transfers power to wheel with more traction | – Balanced performance – Versatile – Adjustable locking action | – Requires maintenance – Can be complex to tune |

| Locked Differential | – Forces both wheels to rotate at same speed | – Maximum traction in straight lines – Excellent for loose surfaces – Predictable power delivery | – Increased tire wear – Compromised cornering ability |

Terrain-Specific Optimization

With a solid understanding of differential types, let’s explore how to optimize your setup for various terrains. Whether you’re racing a touring car on a high-grip asphalt track or crawling over boulders with your scale rig, tailoring your differential to the terrain is essential for peak performance.

Mastering Sandy Surfaces

Sand presents unique challenges for RC cars, particularly 1/8 scale 4WD buggies and truggies. The loose, shifting nature of sand requires specific differential setups to maintain both control and forward momentum.

Real-World Example: Imagine your Losi 8IGHT-T 4.0 racing across a sandy track. With an open differential, one wheel might spin freely in the deep sand, robbing you of speed and control. But with a limited-slip or locked differential, both wheels work together to find traction, propelling you through the turn.

Optimal Setup:

- Primary Choice: Limited-Slip Differential

- Use higher viscosity fluid (500k – 1M cst)

- Tighten ball diff 10-20% more than usual

- Alternative: Locked Differential

- Ideal for straight-line drag runs

- Pair with paddle tires for maximum grip

Tuning Tips:

1. Start with a tighter diff setting, then gradually loosen

2. Monitor diff temps and clean frequently to remove sand

3. Experiment with fluid viscosity based on track conditions

Impact on Performance:

A well-tuned differential can make a significant difference in lap times on sandy tracks. For example, switching from an open diff to a properly set up LSD can lead to lap time improvements of 1-2 seconds or more, depending on track length and layout. The increased traction and control provided by an LSD or locked diff allows you to carry more speed through corners and get on the power earlier on exit.

However, it’s important to balance the diff setup with other factors like suspension tuning and tire choice. A locked diff may provide great forward traction, but if your suspension is too stiff or your tires too narrow, you may still struggle with overall grip and handling. Experimenting with different combinations of diff settings, shock oil weights, spring rates, and tire compounds can help you find the perfect balance for your specific track conditions.

Conquering Gravel Surfaces

Gravel represents a middle ground between sand and asphalt, requiring a balanced approach to differential setup. RC classes like 1/10 scale 2WD and 4WD buggies often race on gravel surfaces.

Real-World Example: Picture your Team Associated B6.1 navigating a gravel-strewn rally course. A well-tuned LSD provides the perfect balance of traction and sliding, allowing you to maintain speed through corners while putting power down on exit.

Optimal Setup:

- Primary Choice: Limited-Slip Differential

- Medium viscosity fluid (300k – 500k cst)

- Adjust ball diff tension based on gravel size and packing

- Alternative: Slightly looser open diff for finer gravel

- Experiment with diff ratios (higher for more rear bias)

Tuning Tips:

1. Test various fluid viscosities and monitor tire wear

2. Adjust suspension settings to complement diff setup

3. Consider staggered front/rear diff setups for tricky conditions

Interaction with Suspension Tuning:

On gravel surfaces, your differential setup works hand-in-hand with your suspension tuning to optimize performance. A well-balanced LSD helps distribute power evenly, but it’s the suspension that keeps your tires in contact with the ground and provides the necessary compliance to maintain grip on uneven terrain.

When tuning for gravel, consider the following suspension adjustments in conjunction with your diff setup:

- Shock Oil Weight: Lighter oil (30-40 wt) for looser gravel, heavier oil (45-60 wt) for packed surfaces

- Spring Rates: Softer springs for increased traction, stiffer springs for more responsive handling

- Ride Height: Higher ride height for deep gravel, lower for smooth hardpack

- Camber and Toe: More negative camber for increased steering, less toe-in for improved straight-line stability

By dialing in your suspension to work with your diff setup, you can achieve the perfect balance of traction, handling, and compliance for the unique challenges of gravel racing. Remember to make small, incremental changes and carefully document your setup to help identify trends and improvements.

Dominating on Asphalt

Asphalt racing, common in on-road classes like touring cars and pan cars, demands precision and finesse. With high grip levels available, differential setup is crucial for maximizing corner speed and acceleration.

Real-World Example: Envision your Tamiya TRF419X diving into a tight hairpin at your local carpet track. A finely-tuned LSD or slightly looser open diff helps the car rotate smoothly, maintaining speed and stability through the corner.

Optimal Setup:

- Primary Choice: Open Differential or Light LSD

- Low viscosity fluid (100k – 300k cst) for maximum efficiency

- Minimal preload for smooth operation

- Alternative: Gear diff for ultra-smooth, high-speed tracks

- Adjust final drive ratio to control wheelspeed and punch

Tuning Tips:

1. Start with a baseline setup, then make small, incremental changes

2. Document all adjustments and monitor tire wear patterns

3. Consider track temp, layout, and grip levels when fine-tuning

Tire Choice Considerations:

On high-grip asphalt surfaces, tire choice plays a significant role in your overall setup. The right tire compound can work with your diff settings to provide the optimal balance of speed, traction, and consistency.

When selecting tires for asphalt racing, keep the following factors in mind:

- Compound: Softer compounds for more traction, harder compounds for longer wear

- Tread Pattern: Slicks for maximum contact patch, treaded for cooler temps or varying conditions

- Foam Inserts: Soft foams for more compliance and grip, hard foams for quicker response

- Rim Width: Narrower rims for more precise steering, wider rims for increased stability

By pairing the right tire choice with a well-tuned differential, you can extract maximum performance from your on-road machine. Don’t be afraid to experiment with different combinations to find the ideal setup for your specific track conditions.

Advanced Tuning Techniques

Fuel-Powered RC Car

- 1:10 Scale big size and full proportional super-fast Drift Car,extra large capacity leak proof fuel tank with the overflow pipe and spring load fill cover for quick re-filling, make you enjoy the toy car for a longer period of time.Independent suspension,6061/T6 solid anodized alum chassis, Oil filled shocks, Solid universal joint cup/high performance ball bearings complete.

Fluid Viscosity Selection

Differential fluid viscosity dramatically affects handling and performance. Here’s a quick reference:

| Viscosity | Characteristics | Ideal Conditions |

| Low (100k – 200k cst) | – Fast response – Minimal power loss – Nimble direction changes | – High-grip, smooth tracks – Consistent traction – Low-torque applications |

| Medium (300k – 500k cst) | – Balanced performance – Predictable transitional behavior – Versatile tuning range | – Varied grip levels – Rougher track surfaces – Diverse temperature ranges |

| High (600k+ cst) | – Maximum drive out of corners – Increased forward traction – Optimized for straight-line acceleration | – Loose, low-traction tracks – High-power drivetrains – Drag racing setups |

Driving Style Considerations:

Your driving style can influence the optimal fluid viscosity for your differential. Aggressive drivers who prefer a more locked-in feel may benefit from higher viscosities, while smooth drivers who prioritize corner speed and rotation may prefer lower viscosities.

Consider the following driving style factors when selecting diff fluid:

- Throttle Control: Higher viscosity for abrupt throttle inputs, lower for precise modulation

- Steering Input: Lower viscosity for quick, responsive steering, higher for more stable tracking

- Braking Technique: Higher viscosity for hard trail braking, lower for gentle brake release

By matching your diff fluid to your unique driving style, you can achieve a more intuitive and comfortable feel on the track. Don’t hesitate to experiment with different viscosities to find the best match for your skills and preferences.

Ramp Angle Tuning (Gear Diffs)

Remote Control Drift Car Building Kit

- Equipped with 4 powerful black furious motors, 1 L-shaped motor, and 1 rechargeable battery, this supercar allows you to control it with exceptional precision. Whether you want to gallop, drift, or spin, this car delivers an exhilarating experience. Scan the QR code on the outer packaging and use the mobile app to explore multiple control modes.

Ramp angles on gear diffs control locking behavior. Shallower angles (20-30°) offer aggressive locking for forward grip, while steeper angles (35-45°) provide smoother, more manageable power delivery.

Factors to Consider:

- Driving style (aggressive vs. smooth)

- Vehicle weight (heavier requires shallower angles for support)

- Gearing (higher speed runs may require steeper angles)

Show Image Figure 3: Cutaway of a gear differential showing ramp angle geometry.

Vehicle Weight and Ramp Angles:

The weight of your RC car can have a significant impact on the optimal ramp angles for your gear diff. Heavier vehicles often require shallower angles to provide the necessary support and locking action under load.

Consider the following weight-related factors when tuning ramp angles:

- Vehicle Class: 1/8 scale buggies and truggies may require shallower angles than lighter 1/10 scale vehicles

- Battery Weight: Heavier LiPo packs may necessitate shallower angles for support

- Chassis Material: Aluminum or steel chassis may require different angles than lighter composite materials

By taking your vehicle’s weight into account, you can fine-tune your ramp angles for optimal performance and longevity. Be sure to make small, incremental changes and test thoroughly to identify the ideal setup for your specific application.

Testing and Development

Successful differential tuning requires a methodical approach to testing. Here’s a step-by-step process:

Baseline Testing:

- Document current setup (diff type, fluid, preload, etc.)

- Run consistent laps, recording times and handling notes

- Identify areas for improvement (e.g., mid-corner, exit)

Incremental Changes:

- Adjust one variable at a time (e.g., fluid viscosity)

- Run multiple laps to gauge the effect of each change

- Record both lap times and subjective handling feedback

- Maintain detailed setup notes for each iteration

Data Analysis:

- Compare lap times to identify trends and improvements

- Evaluate subjective notes to determine setup direction

- Consider tire wear and diff temp data for longevity

- Decide on the optimal setup for current conditions

Example Test Plan:

- Baseline: Open diff, 30k fluid, medium preload

- Best lap: 28.5 sec, push mid-corner, good off-power rotation

- Test 1: 50k fluid, 2 shims less preload

- Best lap: 27.9 sec, improved mid-corner, slight exit oversteer

- Test 2: 40k fluid, 1 shim more preload than baseline

- Best lap: 28.1 sec, balanced feel, controlled exit drive

- Conclusion: 40k fluid, medium-high preload is the best setup

Troubleshooting Common Issues:

Even with careful testing and tuning, you may encounter problems with your differential setup. Here are some common issues and potential solutions:

- Excessive Tire Wear: Check for leaks, adjust fluid viscosity, consider softer compound

- Inconsistent Handling: Verify fluid level, check for worn or damaged parts, adjust preload

- Overheating: Clean diff thoroughly, check for tight spots, use higher viscosity fluid

- Lack of Forward Drive: Increase fluid viscosity, adjust ramp angles (shallower), use stiffer preload

Maintenance and Longevity

Regular maintenance is crucial for peak differential performance and longevity. Here’s a comprehensive schedule:

After Every Run:

- Remove diff cover and inspect for debris or damage

- Check for leaks, unusual noises, or binding

- Monitor diff temp and clean external surfaces

- Re-seal and prepare for next run

Every 2-3 Race Days:

- Fully disassemble diff, cleaning all components

- Inspect gears, cross pins, outdrives, etc. for wear

- Replace seals, thrust washers, or bearings as needed

- Reassemble with fresh grease and oil

- Check endplay and mating of ring/pinion after assembly

Every 2-3 Months:

- Clean and prep different internals for thorough inspection

- Check ring and pinion gears for uneven wear or damage

- Replace any out-of-spec components (gears, pins, outdrives)

- Inspect housing for hairline cracks or stripped threads

- Rebuild with new different parts as needed

Detailed Cleaning Process:

- Disassemble diff fully, organizing hardware in labeled containers

- Clean all parts with brake cleaner or other solvent

- Blow dry with compressed air; check journals for pronounced wear

- Ultrasonically clean ring/pinion and other critical components

- Visually inspect all parts, replacing any damaged items

- Lube bearings, thrust washers, and cross pins with assembly grease

- Fill gear diff with fresh oil of appropriate viscosity

- Carefully reassemble, setting gear backlash and checking endplay

- Install diff in vehicle and test for smooth operation and efficiency

Conclusion

Mastering differential setup is a continuous journey that blends technical knowledge with on-track experience. By understanding the characteristics of different diff types, how they interact with various terrain conditions, and the effects of tuning adjustments, you can unlock your RC car’s full potential.

Remember, there’s no one perfect setup for all situations. The key is to develop a logical tuning process, carefully documenting changes and results. By following the testing and maintenance procedures outlined in this guide, you’ll be well on your way to optimizing your diff setup for any track or trail.

Of course, the differential is just one piece of the performance puzzle. To achieve the best results, consider how your diff setup interacts with other tuning variables like suspension, gearing, and tire compound. The most successful racers develop a deep understanding of these relationships and adapt their setups accordingly.

We hope this guide has provided you with the knowledge and tools needed to take your diff tuning to the next level. Now it’s time to hit the track and put these techniques into practice! If you have any questions, tips, or success stories to share, please leave a comment below. Together, we can continue pushing the boundaries of RC performance.

Read Other Posts

- The Future of RC Cars: Electric vs. Fuel-Powered Models – An Environmental Perspective

- How to Fine-Tune RC Car Servo Speed Like a Pro: Step-by-Step Guide (2024)

- RC Car Tire Showdown: Foam vs. Air – Which Setup Will Elevate Your Ride?

- Benefits of Brushless vs. Brushed RC Car Motors

- RC Car Telemetry Systems Explained: How Advanced Data Boosts Your Racing Performance