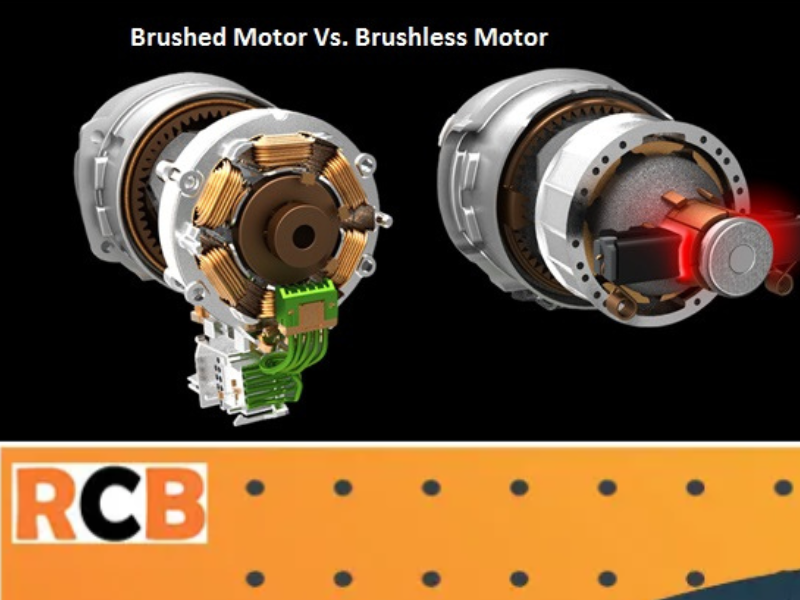

If you’re looking for a motor, you might have come across the terms “brushed” and “brushless.” These two types of motors are widely used in various applications, including industrial machines, drones, Remote Control cars, and more. While both types of motors have the same basic function of converting electrical energy into mechanical energy, they differ in several ways. In this article, we will discuss the difference between brushed and brushless motors, their advantages and disadvantages, and the applications where each is best suited.

Table of Contents

- Introduction

- What is a Brushed Motor?

- How Does a Brushed Motor Work?

- Advantages of Brushed Motors

- Disadvantages of Brushed Motors

- What is a Brushless Motor?

- How Does a Brushless Motor Work?

- Advantages of Brushless Motors

- Disadvantages of Brushless Motors

- Comparison Between Brushed and Brushless Motors

- Applications of Brushed and Brushless Motors

- Conclusion

- FAQs

Introduction

A motor is a device that converts electrical energy into mechanical energy. Motors are used in many different applications, including machines, appliances, Remote Control cars Helicopters, and more. There are two main types of motors: brushed and brushless. Brushed motors have been around for many years and are widely used in various applications. Brushless motors, on the other hand, are a more recent development that has gained popularity due to their superior performance and efficiency.

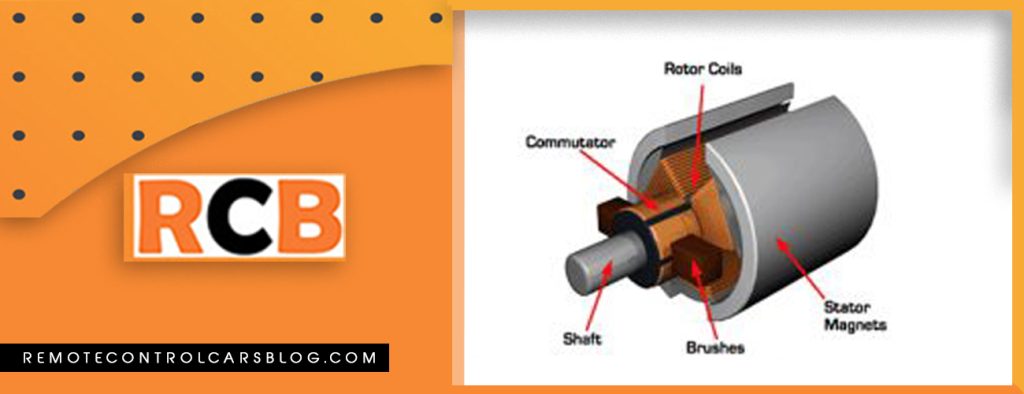

What is a Brushed Motor?

A brushed motor is an electric motor that uses carbon brushes to transfer electrical energy to the motor’s rotating armature. The armature consists of a series of copper wire windings wrapped around an iron core, and the carbon brushes are located on the motor’s stationary housing. The brushes make contact with the armature’s commutator, which consists of a series of metal segments that are electrically insulated from each other.

How Does a Brushed Motor Work?

When an electrical current is applied to the motor, it flows through the carbon brushes and into the armature windings, creating a magnetic field that causes the armature to rotate. As the armature rotates, the brushes make contact with different segments of the commutator, reversing the direction of the electrical current and causing the armature to continue rotating.

Advantages of Brushed Motors

Brushed motors are relatively simple and inexpensive to manufacture, making them a popular choice for many applications. They are also easy to control and can provide high levels of torque at low speeds. In addition, brushed motors are typically more durable and can withstand higher temperatures than brushless motors.

There are multiple advantages to using Brushed motors in the divides. Some of the most common ones are

- Low Cost

- Extended Life

- Controller Cost

- Fixed Speed

- Operational environment

Let’s discuss these features one by one

Low Cost

The brushed Motors do not require some circuits. The direction and the amount of the current is controlled through the self-controlled mechanism. This is the reason why the overall cost for the construction of the brush motor is low

Extended Life

Brushed Motors are relatively simple. This is the reason that repairing these Motors is also possible in a simple manner. Not very high-tech instruments and spare parts are required for the repair of these Motors. Therefore it is really very common to rebuild the Motors again. As the Motors can be rebuilt again so this is the reason that the machines can be used again and again. So life can be extended as we can rebuild these Motors

Controller Cost

As mentioned before that these Motors are not using very advanced technology. Therefore the spare parts and instruments used in this motor are not very expensive. In most places, we need a controller to control the speed of the motor. In the case of this motor, we can really use them in expensive controllers. So this is really a cost-cutting trick by using inexpensive controllers.

Fixed Speed

Sometimes we have Motors that are fitted Into specific machines which operate with are needed to operate at a single speed. This means the variation of the speed is not needed in that particular machine. As the variation is not needed in the machine this means that you do not require a speed-controlling mechanism for your machine. Congratulations you just saved a good amount of money while using the brushed machine.

Operational environment

The brushed Motors are simple. But this does not mean that these are pretty children. They are really strong ones. They have the capacity and the ability to work even in very extreme conditions. So here you are dealing with some strong machines that have good muscles to show. These can really work in extreme working conditions.

Checkout Our Blog For More Information On Remote Control Vehicles

What is a Brushless Motor?

A brushless motor is an electric motor that does not use carbon brushes to transfer electrical energy to the motor’s rotating armature. Instead, the motor uses electronic commutation to control the armature’s rotation. Brushless motors are sometimes referred to as “electronically commutated motors” or “ECMs.”

How Does a Brushless Motor Work?

Brushless motors use a permanent magnet rotor and a stator with multiple coils of wire wrapped around it. The coils are connected to an electronic controller that uses sensors to detect the rotor’s position and adjust the current flowing through the coils to control the motor’s rotation.

Advantages of Brushless Motors

There are multiple advantages to using Brushed motors in the divides. Some of the most common ones are

- Maintenance Effort

- Rated Load

- Size Ratio

- Thermal Characteristics

- Speed Range

- Noise Generation

Let’s discuss these features one by one

Maintenance Effort

The brushes are not installed in the Motors so the maintenance required for the brushes is not needed at all. It means the low effort needed to maintain the machine and the lower expense of the maintenance efforts.

Rated Load

Rated load functionalities are available in the machine. This will certainly increase the operational efficiency of the machine. It does not matter at which specific Speed the machine is running.

Size Ratio

The power-to-size ratio is excellent. Do not consider its small size. It can surprise you with higher output power.

Thermal Characteristics

The reduced size can surprise you with the thermal characteristics that are superior and can bring smoothness to the functionality.

Speed Range

Due to the use of modern-day technology, these Motors can provide a variety of speeds that can be used in various functionalities.

Noise Generation

The highest speed functionality may make you think that it will create noise pollution. Do not worry about noise generation. It really produces very little noise.

Comparison Between Brushed and Brushless Motors

| Brushed Motors | Brushless Motors | |

|---|---|---|

| Cost | Inexpensive | Expensive |

| Efficiency | Less efficient | More efficient |

| Maintenance | More maintenance required | Less maintenance required |

| Durability | More durable | Less durable |

| Noise and Vibration | More noise and vibration | Less noise and vibration |

Applications of Brushed and Brushless Motors

Both brushed and brushless motors have their unique advantages and disadvantages, making them better suited for different applications. Brushed motors are often used in applications where cost is a significant factor, such as power tools, toys, and some household appliances. Brushless motors, on the other hand, are often used in applications that require high efficiencies, reliability, and precise control, such as drones, electric vehicles, and industrial machines.

Conclusion

In conclusion, the main difference between brushed and brushless motors is the method used to control the motor’s rotation. Brushed motors use carbon brushes, while brushless motors use electronic commutation. While both types of motors have their unique advantages and disadvantages, brushless motors are generally more efficient, reliable, and require less maintenance than brushed motors. However, they are also more expensive and require more sophisticated electronic control systems.

Checkout The Advantages And Disadvantages Of Gasoline Powered Remote Control Cars

FAQs

Q: Which motor is more efficient, brushed or brushless?

Brushless motors are more efficient than brushed motors, as they do not have the friction and voltage drop caused by brushes.

Q: Which motor is more durable, brushed or brushless?

Brushless motors are more durable than brushed motors, as they have fewer moving parts and less wear and tear.